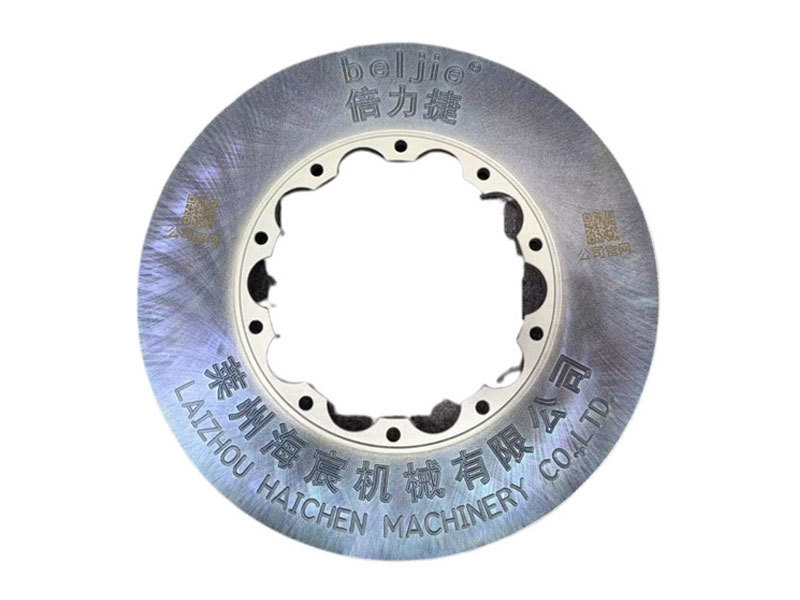

Hub

Product Classification:

Balance

The balance accuracy is less than 1080g/mmm2, and balanced braking is realized, and the performance is second only to the original brake disc.

Heat sink

Achieve better heat dissipation, prevent brake disc deformation and ensure friction

Surface treatment

High-quality surface treatment of friction surfaces in secondary machining operations

Positioning hole

High-precision hole diameter and precise positioning of the disc body

Email:Brake@hubrotor.com

Product Introduction

The wheel hub is a cylindrical, centrally mounted metal part of the tire that supports the tire. Also called wheels, steel rings, wheels, tire bells. There are many kinds of wheels according to the diameter, width, molding method and material.

The hub is also called the rim. According to the characteristics and needs of different models, the surface treatment process of the wheel hub will also adopt different methods, which can be roughly divided into two types: baking paint and electroplating. The appearance of the wheels of ordinary models is less considered, and good heat dissipation is a basic requirement. The process is basically treated with baking paint, that is, spraying and then electric baking. The cost is more economical and the color is beautiful, and the retention time is long, even if the vehicle is scrapped., The color of the wheel remains the same. Many Volkswagen models wheel surface treatment process is paint. Some fashion avant-garde, dynamic color wheel is also the use of paint technology. This kind of wheel hub moderate price, complete specifications. Electroplated wheels are divided into electroplating silver, water plating and pure plating.

Processing capacity

Previous Page:

Next page:

Online consultation

Related Products